This is a short post about a simple thing - hardly worth it you might think, but simple things sometimes trip us up.

I'm working up to building the bottom end, cleaning the crankcases, checking the oilways, things like that. I fitted the oil pickup pipe with a sealer called Permatex No.1, on the advice of some club members - it sets solid and that can be useful in some applications:

Here it is in place. You can also see one of the extended studs I fitted - the sump I am using is considerably thicker than standard. The studs are fitted with Loctite medium strength threadlock.

And another picture from underneath:

This is where it all goes a bit pear shaped. In the next picture you can see that the pickup pipe doesn't fit through the hole in the strainer - one of them is wrong, and this illustrates one of the pitfalls of building old bikes from bits. There is a question over which one is wrong, exacerbated by the knowledge that the strainers fitted to Huntmasters are not the same as those fitted to BSA A10s.

Now, we all know that 'the Huntmaster uses a BSA A10 engine', but actually surprisingly few parts are common. You would think, given that the crank and rods are the same and the crankcase is identical in some areas (not those relating to the timing chest, which is a different shape) that a simple thing like a sump strainer would be common too - in fact, wouldn't the canny design engineer use the bit that was already available in BSA stores? Well, no. And this my friends is perhaps indicative of why our laudable, innovative motorcycle industry went to the wall.

After contacting several experts, it transpires that the sump strainer is indeed different. Given that the strainer was manufactured by SRM (famous for BSA A10 parts) I thought perhaps I had been supplied the wrong one; apparently not. Draganfly Motorcycles, who I bought it from, actually modify the SRM A10 part into a part suitable for the Huntmaster by moving the hole.

We Ariel owners would be lost without them.

It turned out that the pickup pipe was bent - easily fixed when you know what you are aiming at.

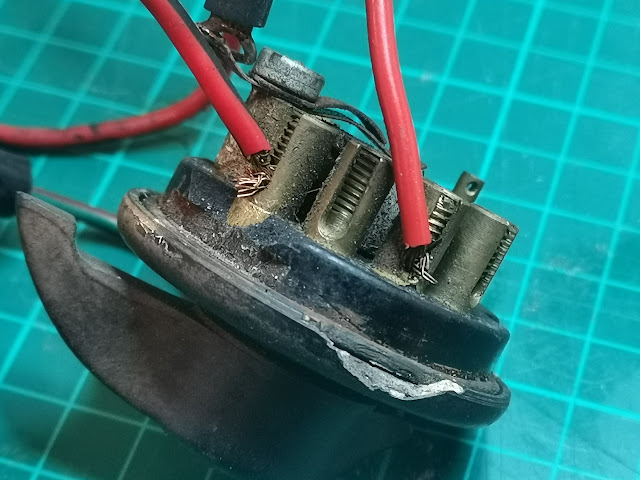

With everything now fitting together, I decided to use Permatex again to seal the strainer to the sump plate, on the basis that the original pressed metal sump plate would have been sealed to the gauze strainer somehow as they were supplied under one part number and there is only one gasket listed in the parts book:

I greased the gasket on both sides as this is a service item and I would expect to remove it periodically.

All that remains then is to fit the sump plate. It's got a magnetic trap and this is deliberately oriented away from the pickup pipe to stop the magnet affecting the performance of the ball valve.