Sunday brings the first VMCC run of the year, the first of many I hope. The W/NG is at son Tom's house with a dead speedo, so the first trip of the day is to go down there, meet up and replace the speedo cable.

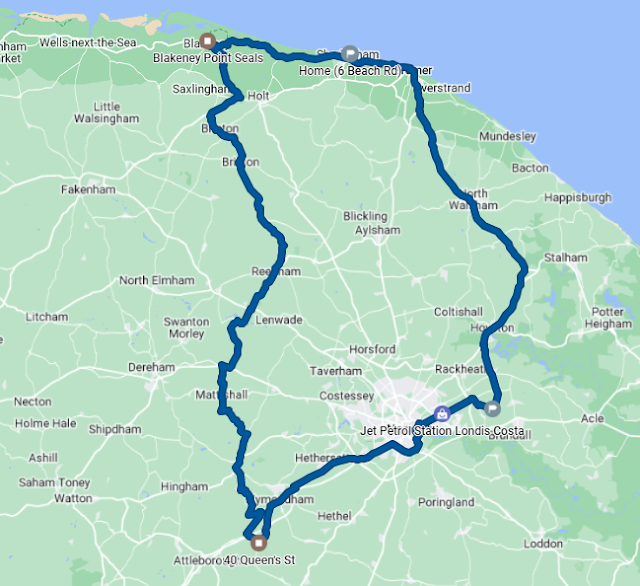

That done, it's off to the start point at Spooner Row just outside Wymondham via a petrol stop.

We arrive on time (for the first time!) and sign on, grab a cup of coffee and are welcomed by the crowd falling easily into chatting about our bikes and where we have come from. One or two remember us from Letheringsett 2022 and from a Blue Sky run I did on my own a few years back. At 11, we set off for Blakeney, a 40 mile trip through the Norfolk countryside. Tom leads, as both bikes have route rollers now:

Tom leads that is until his speedo cable snaps again at 7 miles into the run, 27 miles into the day. Tulip sheet navigation is tough with no speedo! I take over, and we arrive safe and sound at Blakeney Quay, for coffee and a burger from

Birdys Bakehouse, and very nice it was too.

Tom shares my enthusiasm for Scott motorcycles:

We are joined by one of their owners, who gives us a guided tour of their eccentricities:

There are some more pictures here, on the Norwich Section VMCC website.

Tom and I part on the way home - he's riding the SQ4, as there is a lot of oil coming from the rear of the top end of the W/NG and the speedo needs fixing again. That's 85 miles - hardly fault free but neither of us stopped unexpectedly.

Bring on the next one!