It took a few days, but with the help of the guys in the AOMCC I finally got the rear mudguard to luggage carrier bracket right!

Wednesday, 30 December 2020

Monday, 28 December 2020

W/NG - getting rid of the fouling problem

It was all my fault. When it arrived from Italy, the W/NG had a 276 fitted and I renewed the needle jet for the 276 because the one in it was knackered, and all was well. Then I found a really good 275 body, marked for a W/NG and I swapped the needle jet and main jet into it with a new slide and needle. Of course, the 276 uses a 107 needle jet and the 275 needs a 106 so I had unwittingly installed the wrong one, so finding that improved the situation.

It was a good run though and she was humming along getting to 50 easily on the flat, though of course I am being very careful not to stress the newly rebuilt engine.

QR50 - Frame: can't see the wood for the trees

Something has bugged me about this bike for a while, something I couldn't quite put my finger on. It started with a Honda publicity picture showing an exciting red dirt bike, typical of their 80's dirt bikes, and a dirty old relic in an ebay picture which strangely gave no hint of Honda's magic.

One day, fitting the silencer and trying to determine the right position relative to the frame and engine I saw what I had been missing. Take a look:

I had been using this picture to scale the size of the silencer:

Seeing it for the first time, I realised why the seat didn't fit properly and how the rear wheel had come to wear a hole in the mudguard. It took half an hour to get the bike off the bench, lift the frame off the engine and remove the forks.

I put the frame in the vice, holding the rear frame loop on one side and applied some heat - the frame soon moved, and I flipped it over to bend the other side. I made the bends gradually, turning the frame each time so that I could be sure that the bends were going in the right place and that I did not overdo it.

The seat now fits properly, with the rear bolt holes aligned with the frame lug.

Sunday, 20 December 2020

Mini-Lathe - Cutting fluid feed

Doing a lot of parting for the various fasteners I am making at the moment led me to contemplate improving the manual drip oil bottle approach I have to feeding cutting fluid, which led me to eBay and YouTube to see what others were doing. A bit of slow-time at the computer led me to a simple drip feed oiler solution and as I’m lucky enough to have a lifetime of oddments knocking around the workshop, I thought I could easily build something without spending any money.

The solution started with a bit of 3/16” copper brake pipe, which I bent into a ‘question mark’ shape, squaring one end and filing a shallow angle on the other. It’s held by a piece of black Acetal round bar, cross drilled 3/16”. The plastic bar is very short, about 3/4”, and has a strong circular magnet attached to it with an M5 countersunk screw which is threaded directly into the Acetal:

The copper pipe is shaped so that the magnet can sit out of site behind the splashback. There is a pvc tube (fish tank air line) attached to the copper tube which leads to a valve, again a fish tank component:

The valve is metal, to avoid any compatibility problems with cutting fluids and plastics and is there to shut off or restrict the flow of oil. The fluid comes from a washing up liquid bottle (told you it was cheap) hanging on a hook on the wall and full of oil:

Fully open, the oil drips at a reasonable rate:

Tuesday, 8 December 2020

FH - Swinging Arm bushes

A while ago, last May in fact I removed the SilentBloc swinging arm bearings and I wrote about it here. Since then, lots of things have got in the way - not only the Honda stuff, the QR50 and the CX500 but also the rear mudguard and the oil filter for the FH and of course the W/NG engine rebuild. Anyhow, as regular readers will know, the oil filter is done and I am on to the swinging arm. I'm doing this next as I want to check the oil filter will fit (and can be re-fitted) with the FERC in place and I can't do that without the swinging arm fitted, so here goes.

Before I start, the inspiration for this job, the details of the bushes and indeed the spindle (and it's machining) came from Steve Carter, who's done more miles on Huntmasters than probably anyone alive today and who is a stalwart member of the AOMCC and a daily contributor to the AOMCC forum.

Thanks Steve.

So, I have two oil filled bronze bushes measuring 22 mm ID x 32 mm OD x 50 mm long that I bought from Simply Bearings under the part number AM2232-50. The cleaned out journals for the old SilentBloc bushes measure exactly 1 1/4", which is 31.75 mm and we will want an interference fit of maybe 0.002" or 0.05 mm.

Well, you know what is coming next don't you. Charlie will start banging on about the virtues of his mini-lathe. What puzzled me for a while was how to hold the bushes to machine the outside diameters to size - I considered expanding mandrels, grub screws in a mandrel and Loctite. I was nervous of using Loctite as the these bushes are porous and I was worried about getting the bush off the mandrel.

As it happened, I just went for it and did it. This Ever Build cyanoacrylate is old and cold and may not work very well but I put a 1/4" wide ring of it around the 22 mm mandrel and slid the bush on - in a few minutes it was set.

I machined the bushes quickly and easily to size using the power feed and a carbide tipped left hand tool running at about 400 rpm. and it cut beautifully with no complaints from the glue. Actually, the cutting forces probably don't test the glue very much as this bronze is quite soft.

When considering fits, I had thought about cutting a clearance fit and using Loctite 603 Bearing Retainer, but discarded the idea as I should be able to machine a reasonable interference fit and not require a liquid retainer. As it turned out, this worked beautifully with the first bush which had a medium driving fit, but I cut the second one slightly undersize so I used some retainer with that. They both held up to the reaming forces.

The mandrel knocked out very easily and the bushes were pushed in flush with the end of the swinging arm tube, since I knew that there was minimal end float with the swinging arm in the frame:

With the reaming done, I could oil and fit the spindle - fortunately it fitted both sides simultaneously with out any adjustment, so I was lucky - I had taken no precautions to align the bush I was reaming with the other bush.

The fit is great - there is no play that I can feel on the bench, though it may be a different story when the bike is on the ground.

Thursday, 26 November 2020

Model A - Battery Strap

In the interests of my sanity (I don't think I will be renovating another Honda in a hurry) I have made a small start on the Model A sheet metal repairs, by welding up the battery strap.

Thursday, 5 November 2020

Charlie's Shed - Cables & Cable Making

This is the section where we deal with those cables that you oil regularly, that operate your clutch and your front brake. They are an important part of your biking experience, not only for your safety but also to make the experience a pleasant one – there something rather magical about you & your bike cruising smoothly along a sunny lane, with everything operating as it should. One of your main connections to your bike is through those control cables:

Cables & Uses

When you have bought your inner wire, store it carefully. One of the key elements of successful soldering is cleanliness - solder will not 'take' to greasy wire or to wire that has been out in the weather for a while. The inner cable should be free of grease and the plated wires should be shiny - dull corroded wires may not solder at all.

Outer Casings, Nipples, ferrules, inners etc.

Inner Cables & Ferrules

Nipples

Sometimes, nipples are fitted with plastic sleeves to reduce friction. These can get mangled but you can make a sleeve (here's how I do it) to replace them:

Buying Parts

Making up a cable

Routing & Laying Out

Cut the Outer Casing

Ferrules

First Nipple

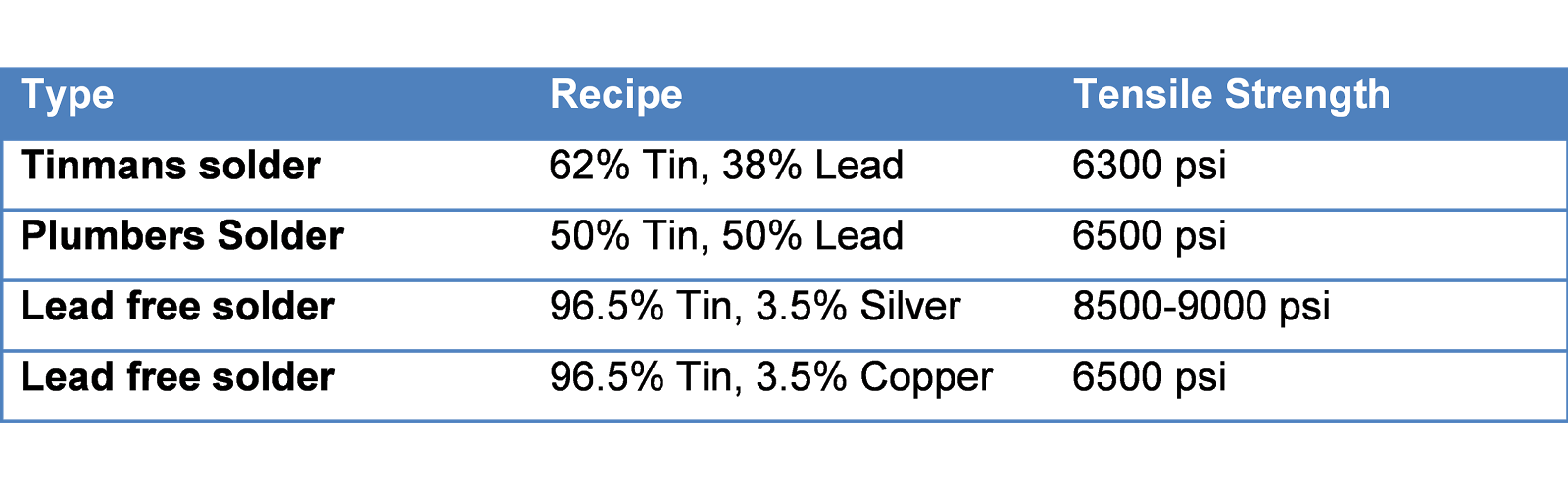

Soft soldering on the other hand involves the use of solder containing various proportions of tin and lead, and temperatures of below 400°C, which will not risk annealing the steel wire. Soft solder can be heated using an electric soldering iron or a solder pot, and the temperature will be easily controlled avoiding the risk of oxidisation or weakening the wire.

So, now we can remove the swaging jig and see that the wire nest fits nicely inside the nipple. We are ready for soldering. Hold the inner cable in the vice, gently, such that the nipple is pointing downwards. We want the solder to flow into the nipple and to stay out of the inner cable; otherwise the inner cable will become stiff and your lever action will be affected.

You'll find it much easier to solder the nipples if you have a solder pot, like this one:

Once cool, clean all the flux off with water. Flux is highly corrosive and you don’t want damage arising from yet more oxidisation. File any excess solder away, and don’t worry if you file off the ends of some strands that are poking out.

Second Nipple

Lubrication

Cable Management

Ariel made use of some rather neat steel sprung cable clips. Here are two three-cable originals on my W/NG, retaining the rear brake switch wiring - there are further ones under the tank retaining the clutch, throttle & air cables. These clips are available in stainless steel for one, two or three cables:

Monday, 2 November 2020

SQ4 - low batteries and flashing lights

The batteries on the SQ4 are now seven years old and are coming to the end of their life, as witnessed by a complete failure to start earlier this year, remedied with the CTEK charger, and a short trip out a few days ago. This one was odd - I had left it idling on the bi-starter to warm up and all was fine (though of course at that speed it wasn't charging). I then took it out and it had no power, eventually dropping onto three cylinders within a few hundred yards of the house - I travelled 1/2 a mile in all, none of it at high enough speeds to charge the battery.

Getting home, the multimeter showed my batteries were down to 5.5 V or so. New batteries are on the horizon!

In the meantime, picking up on a thread in the AOMCC forum I had bought a battery condition monitor from Gammatronix:

I've chosen to fit it in the top of the dummy battery box. It fits in a 14mm hole which I cut with a cone drill.

I've sealed it with some silicone on the outside:

There's a further map #6, which is for low current applications and shows a slow red, yellow or green blink according to voltage level.

Here is a very exciting video of a LED flashing green. Tell your friends, it is riveting stuff:

Eagle eyed readers will see the CTEK charging connector I have fitted in the background.