It looks like a detail, maybe even a sign of obsession, but choosing the right thread is actually really important.

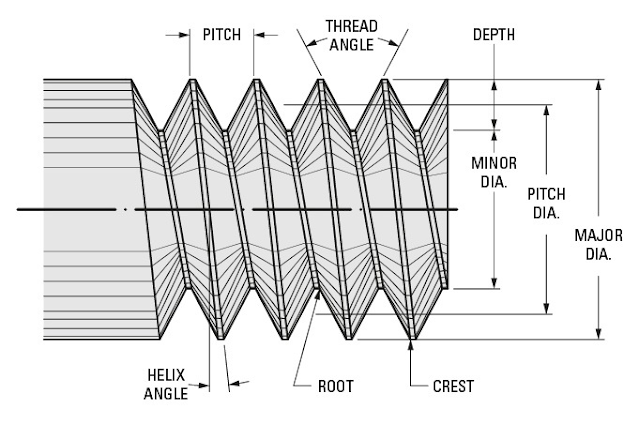

I've been working on the forks this week - you may have noticed - and one of the bolts I removed was conspicuously coarse - it was a 3/8" BSW bolt, 1 3/4" long: the front wheel spindle clamp bolt. British Standard Whitworth threads are coarse (20 threads per inch) and consequently strong for their size. What they are not good at is staying tight when subject to vibration. You use them in alloy, but you will find that virtually all the other threads on a bike of this vintage are British Standard Cycle, which in this size is 26 threads per inch. The helix angle in a 26 tpi thread is much smaller than that in a 20 tpi thread, and consequently the thread is much less likely to work loose under vibration.

It also pays to choose the right length - this application needs a 1 1/2" bolt, so that most of the threads are hidden in the nut and don't get filled up with debris from the road.

No comments:

Post a Comment